Product List

Abrasive Wheel Saw

The TB0150 Precision Diamond and Abrasive Wheel Saw is designed to cut with minimal deformation a wide variety of fragile or soft materials. Solidly built, this instrument can meet the most demanding requirements of laboratories, offering high precision and flexibility.

Equipped with a micrometer for precise positioning of sample over 25mm range and with a digital speed display controller operated through a keypad, TB10150 is constructed from a cast-aluminum frame and stainless steel components, providing stability and corrosion resistance.

The sample arm includes a system of three weights used for precise control of the downforce of the sample against cutting disk.

The AC 1/4hp motor with inverter is operated by the digital controller to rotate the diamond wafering blade or abrasive cut-off wheels of 3 inch (75mm), 4 inch (100mm), 5 inch (125mm) or 6 inch (150mm) diameter with speeds range from 0 to 1000 rpm.

A transparent polycarbonate splash/safety shield with an integrated safety switch is fitted to prevent operation when the shield is open.

An endpoint microswitch indicator can be set to terminate the cutting process at a predetermined depth.

The recirculating coolant system consists of a coolant reservoir with an adjustable power supply, liquid recirculation pump, twin coolant tubes, stainless perforated tray, sample retrieval tweezers and sump drain tool. The system provides adequate coolant flow to the twin coolant tubes located on either side of the cutting wheel. The recirculating coolant system accepts the delivered cutting fluid.

Applications

Materials: Slicing samples of metals, alloys, composites

Ceramics: Slicing samples of ceramics

Semiconductor: Cutting semiconductor crystals and sectioning embedded devices

Pathology: Cutting bone and teeth material and preparing thin sections. Cutting embedded tissue

General Physics: Mounting and slicing single crystals along a particular axis

Geology: Preparing mineralogical sections of rocks

Paleontology: Preparing sections of fossils in rocks

| Technical Specification | |

| General | Compact size bench top laboratory equipment |

| Pivot specimen arm with load weight and adjustable counterbalance weight with threaded shaft for adjusting the pressure of sample against disk during cutting | |

| Adjustable cutting depth | |

| Precise sample positioning | |

| Speed range | Electronic adjusted between 0 - 1000rpm, displayed digitally on front panel keypad |

| Stage lateral travel | Manual, up to 25 mm with reading of slice by a micrometer with resolution of 0.01mm |

| Spindle | Stainless Steel ½ inch (12.7mm) diameter with standard flanges, belt driven |

| Cutting Depth | Manual adjusted, microswitch for stopping the cutting process at a preset depth |

| Sample stages | Screw Holder for Irregular Samples included in standard delivery |

| Variety of sample holders can be attached | |

| Cutting wheels & blades outer dia. | 3 inch (76mm), 4 inch (102mm), 5 inch (127mm) and 6 inch (152mm) |

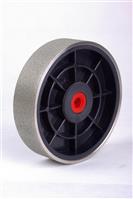

| Cutting wheels & blades types | Broad range of cut-off wheels and diamond wafering blades targeted for various materials sectioning: |

| Aluminum Oxide Abrasive Cut-Off Wheels | |

| Silicon Carbide Abrasive Cut-Off Wheels | |

| Diamond Wafering Blades | |

| Cooling | Recirculating coolant system including: |

| stainless steel perforated tray | |

| adjustable power supply | |

| coolant pump | |

| win coolant tubes | |

| sample retrieval tweezers | |

| RCS drain tool | |

| Motor | 110 - 115V or 220 - 240V |

| 1/4hp (180W) | |

| Safety | Transparent Polycarbonate Splash/Safety Shield with safety micro switch |

| Product dimensions | W × H × D: 12” × 8” × 16” |

| Weight | 40 lbs (18kg) |

| Standard Warranty | One year limited with life time support (not including rusted parts due to inadequate storage conditions) |

Applications

In addition to the industrial applications, these saws are also used within:

1.Metalography

2.Geology

3.Archeology and paleontology

4.Criminology and forensics

5.Biology

6.Pathology

7.Histology

Anatomy and dentistry

| Technical Information | |

|

Design Cutting Feed Primary Voltage Secondary Voltage Auxiliary voltage Electric motor Primary fuse Secondary fuse WiFi Machine weight without accessories : Overall dimensions Machine control Drum diameter Pulleys diameter CE Certification USB Output Possible wire diameter Wire length Wire speed Wire tension for 0.22 -0.3mm Wire tension for 0.10 -0.17mm Cleaning of wire Max. sample weight Max. sample dimension Warranty |

Vertical Gravity (±300g) 230V / 50-60Hz 36Vdc 24Vdc 36V DC - 8A - 200W Ø 5 × 20 - 250 V - 2 A Ø 5 × 20 - 250 V - 10 A Ready, WiFi B/G 13.8kg L × B × H ; 401 × 345 × 455mm Tactil resistive screen 600 × 480 pixels 83mm 80mm CE 5V / 400mA 0.10 - 0.30mm 10m 0 - 3.6m/s 2kg 1kg With cutting liquid diluted 5% or water 2500g 50 × 50 × 50 mm - Ø 50mm 12 months |

English

English Russian

Russian Spanish

Spanish